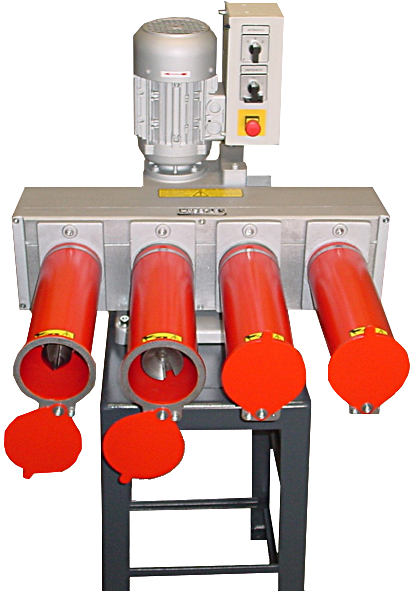

Haberle hr300 series

Deburring Machine

SPECIFICATIONS for the HABERLE HR300 of deburring machines

Electrical Equipment

3-phase 2-speed motor, 60 Hz: 220 V, 440 V or 575 V, 1.1/1.5 kW

Speed selective switch, lockable main switch with thermal overload protection, emergency stop mushroom button. In Europe and USA standard with low-voltage trip.

Spindle Speeds, 60 Hz

HR 302: 120/240 RPM

HR 301 and HR 304: 60/120 RPM

Tool Holding(s) with protective Cover

Each tool holding with Morse Taper 3 is protected by a steel cover with shutter for best operator's safety.

Standard Equipment

Reducing holdings Morse Taper 2-3, drift key, operating wrenches, manual with parts list.

Optional Equipment

KOPAL tools and fabricated steel stand.

Cutting Range ( includes chart)

Concentric chamfer thanks to the spring-loaded pilot which locates the workpiece automatically before the knife starts to chamfer. Available total angle 90° for 45° chamfer, or 60° for 30° chamfer. Models 60.100 only available with total angle 90°. Attachment: Small tools = CM-2, Mod. 40.80 and 60.100 = CM-3.

Slow speeds and only one knife edge allow feeding by hand. Short work pieces hold with manual grip device for best safety. Large burrs from rough cutting remove separately to get an accurately concentric chamfering.

Chamfering Knife

Replaceable knife HSS-E (Cobalt alloyed0, two edges to change, easy to sharpen.

Available cutting angles according to the workpiece:

Mild + stainless steel, copper, aluminum, plastics: 20°

Steel, bronze and hard plastics (e.g. Plexiglass): 14°

Brass and cast iron, hard bronze: 0°

Order Examples for KOPAL Tools

KOPAL Model 2.42-INT., total angle 60°, rake angle 20°

Knife for Model 2.42-INT., total angle 60°,rake angle 20°